Every spring Master Recycler course graduates take a tour. The annual Spring Tour this year included four stops. Here are short descriptions that participants wrote up about what they learned.

Sunderland Yard: Story by Diane Larson (Class 30) Sunderland Recycling Facility has won national awards for its work in recovering waste related to roads in Portland. Sunderland Yard performs two types of recovery:

- Crushing: Takes clean asphalt and concrete from city maintenance projects (or from small contractors repairing sidewalks and driveways) and crushes it into gravel to be used for road base and trench fill.

- Composting: Takes leaves from city streets and fall leaf depots and turns them into compost to be used as soil amendment or erosion control.

In addition, Sunderland Yard takes street “sand” picked up by street sweepers and screens it for reuse. Some “sand” is actually what’s called “dirty rock,” which works better on roads during wintry weather. The facility is funded by gas tax revenues and parking meter revenues as well as by fees for gravel, asphalt and compost which are all available to buy.

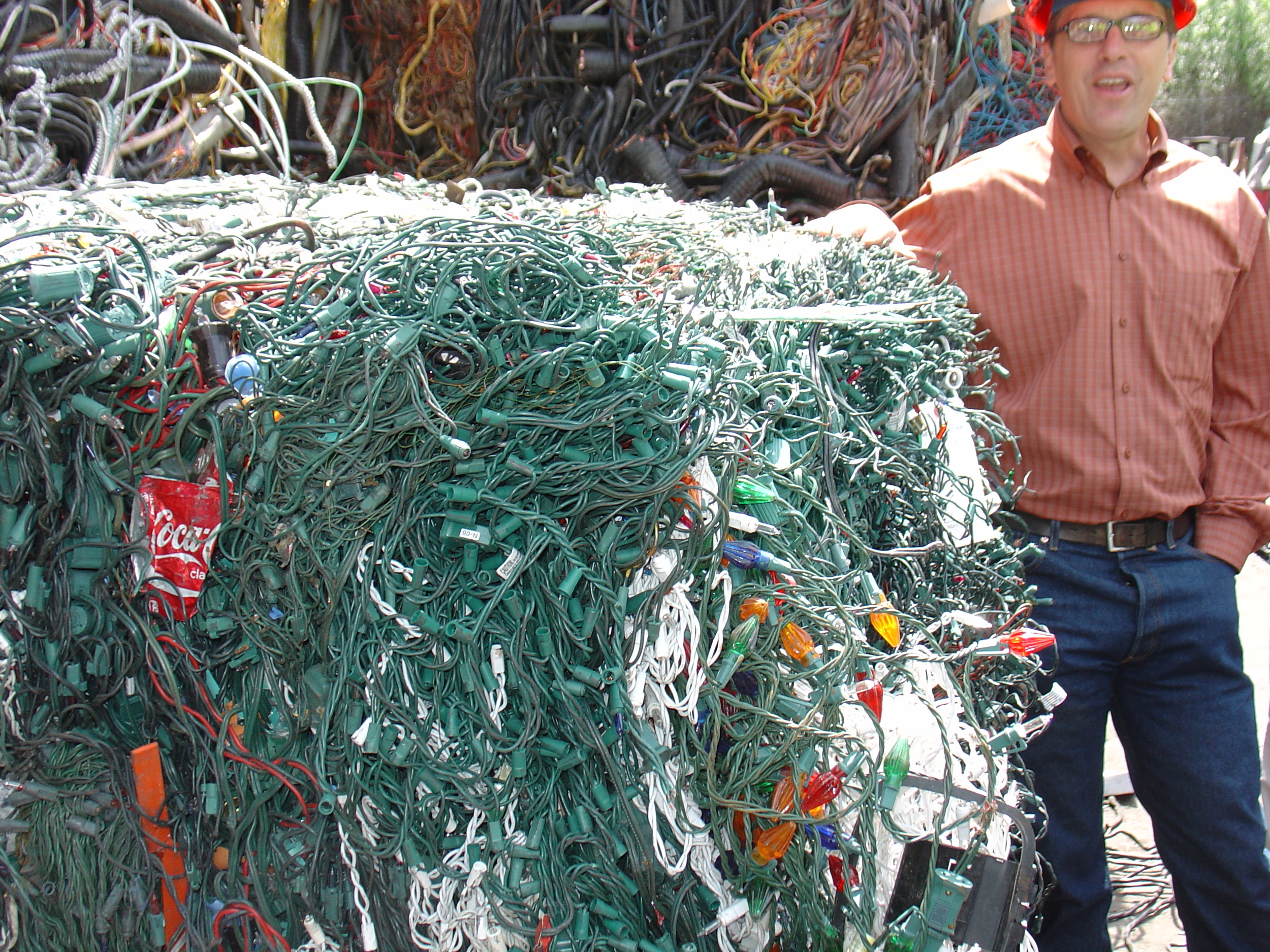

Metro Metals Northwest: (Story by Serena Ross Class 37) Metro Metals NW is a scrap metals recycler located on 18 acres in North Portland off of Columbia Way. They process thousands of tons of metal per day and turn around their inventory in a matter of weeks. Two types of scrap metal are received. Ferrous metal, which is magnetic and defined by anything containing iron, is bought by the ton. Non-ferrous metal, such as aluminum, copper and bronze, is not magnetic and is bought by the pound. Tour-goers explore piles of gravel, sand and dirt at Sunderland Yard.

Metro Metals takes in everything from huge truckloads of steel, entire cars and appliances to be shredded, and industrial metal shavings, down to Christmas tree lights and gutters from your house. They do not take any hazardous metals including mercury or radioactive items. Each non-ferrous metal commodity has its own price per pound so must be separated by type before it can be priced. Much of the scrap metal these days ends up being sold overseas and Metro Metals typically exports about 200 containers per month.

Metro Metals NW has done considerable work to alleviate environmental issues of contaminated storm water draining into the water ways. They have built a storm water waste treatment facility on-site to process all the storm water that hits the pavement at their location.

Owens Illinois Glass (by Jaylen Schmitt, Class 38) Located on the aptly named Glass Plant Road in Northeast Portland, Owens-Illinois has been recycling glass since 1956. At that time its furnaces were powered completely by electricity, but in 1986 the source of power for their melting furnaces was switched entirely to natural gas.

The facility currently operates two of four furnaces, burns 80,000 cubic feet of natural gas per hour and recycles 400 tons of glass per year. The furnaces are continuously fed to a depth of five feet – approximately 750 square feet of glass being melted at any given time.

The glass comes from beverage container recovery stations (like at Fred Meyer stores) and from local MRFs. Owens-Illinois makes containers for over 250 customers – some local – providing them with bottles for microbrews, wine, pickles and other products. The beverage containers Owens-Illinois produces are made with 65% On the line at Owens Illinois.

recycled glass mixed with 35% raw materials such as limestone, silica or soda ash depending on what color the glass will be. The crushed, recycled glass cullet is mixed with raw materials depending on container type and color and sent to the furnace for melting where the temperature reaches 2750 degrees Fahrenheit. A stream of melted glass is then cut into gobs. The gob is put in to a mold where the opening of the container is formed first. It is then inverted where the rest of the container is blown into shape. The glowing hot, formed bottle is then put on a conveyer belt and transported through a cooling process where it first gets a mist of tin and then plastic sprayed over the outside to make the glass non-sticky (glass will stick to itself or other bottles without this coating). The bottles are then packaged for shipping. When the recycling facility is operating at full capacity, the glass plant can produce a million and a half bottles per day.

Oregon Food Bank Story by Kacia Brockman (Class 26) This may look like a picture of a rather generic, boring old box. Even its label is vague: “vegetable creamy soup.” But in reality it is one of the many interesting stories about how Oregon Food Bank and local businesses are working together to end hunger and reduce the waste of food in Oregon.

The Food Bank found that they would often get donated odds and ends that they couldn’t package and distribute. So Pacific Foods agreed to take these items and make soup with the ingredients. They donate the labor and packaging and send it back to the Food Bank, a unique soup every time.

The Food Bank’s Harvest Share program recovers perishable food from local farmers and grocers and redistributes to families in need, farmers’ market style. They also offer gardening and cooking classes to help residents become more self sufficient. And in addition to their daily operations, the tour was timed perfectly to witness the thousands of boxes of food donated by the Annual Letter Carrier Food Drive.